Optimize Schlieren Projects with Chronos High-Speed Cameras

Chronos highspeed camera systems offer the portability, ease-of-use, and video quality required by Universities and R&D Labs to understand Schlieren Imaging in-depth.

What is Schlieren Imaging?

Schlieren Imaging is a technique that allows us to see the subtle changes in the refractive index of fluids. It can reveal the flow of air, temperature variations, and shockwaves that are otherwise invisible to the naked eye.

How does Schlieren Imaging benefit from Chronos High Speed Cameras?

High-speed cameras coupled with a Schlieren visualization setup can capture rapid changes in air density or temperature that are not visible by the naked eye. With Chronos High-Speed Cameras, unlock the intricacies of Schlieren Imaging processes and get ready for detailed analysis and visualizations, all with unparalleled efficiency.

Key Benefits:

- All-in-One: Completely standalone, untethered operation with a 5″ inch touchscreen display and battery for portability.

- Clear Imaging: Record events at 1000FPS+ and capture distortions in light

- Playback Option: See your Schlieren footage on your Camera screen for in-depth analysis

- Research Enhancement: Visualize, measure, and comprehend your Schlieren projects

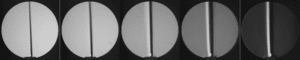

Image 1. Filmed with the Chronos 1.4 Monochrome High-Speed Camera, this Schlieren Imaging cut off percentage increasing with the image intensity decreasing uniformly. The image was captured at 100 fps, exposure time was 250us. From left to right cut off percentage is 0, 25, 50, 75 and 100%.

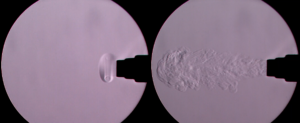

Image 2. Images showing a candle being blown by the air from a heat gun. The video was captured with the new Chronos 4K12 camera. Image size 3840 X 2160, video recorded at 937 fps 8-bit.

Image 3. The initial hot air from from a heat gun. The images were also captured. Similar to image 2, the video was captured with the new Chronos 4K12 camera. Image size and frame rate are the same.

How does Schlieren Imaging work?

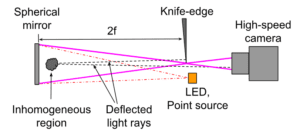

In a uniform medium, light travels without deviation. However, when the medium is disrupted by changes in pressure or temperature, its density fluctuates, altering its refractive index. As a result, a beam of light passing through this changing density can no longer follow a straight path; it bends and twists. Enter the “knife-edge,” a thin, rigid object strategically placed in the light’s path. It filters out the unaffected rays, allowing only those bent by the changing medium density to create the captivating images you’ll see on your screen.

Figure 1. Schematic diagram of the Schlieren Imaging setup

Applications

- Lenses Defect Testing

- Shock Wave Testing in High Speed Fluids

- Gas Leak Testing

A. Main components

The following list shows the different elements in the Kron Technologies’ Schlieren setup. The test rig was used to capture high-speed videos and the images presented at Krontech.ca. The list can serve as a guide for those interested in building a Schlieren imaging setup.

The essential items are the parabolic mirror, the light source, the camera and the knife edge. Other elements are included as well. Feel free to look for other alternatives that allow you to build your Schlieren system in a more cost effective way.

The LED source used, DigiKey product number SST-20-W40H-A120-J5402, is no longer manufactured. Please refer for a similar item at DigiKey.com

B. Extra components

C. Optomechanical components

The different elements used for the Schlieren setup, except the spherical mirror, were mounted on a breadboard. The camera and the knife edge were mounted each on an XY-axis stage for precise placement.

There were also other optomechanical components used. They were purchased at Thorlabs.com.

- Breadboard

- Mounting base

- Post holder

- Optical post

- Right angle clamp

- Mounted Standard Iris, Ø25.0 mm Max Aperture

The XY-stages contain 4mm thread holes while the breadboard has 6mm thread holes. To connect these two components a couple of plates were designed. One was to join the breadboard and the XY-stage. One more plate was used to couple the upper surface of the XY-stage to the optical components.

Feel free to download the files below and make the connecting plates yourself or have them made at the machine shop of your preference.

- Lower Coupling Surface

- Lower Coupling Surface Step*

- Upper Coupling Surface

- Upper Coupling Surface Step*

*Step can be accessed through Intercom

Some things to consider when choosing a high-speed camera for Schlieren Imaging:

Frame-rate

What is the duration and speed of the event?

Chronos range from 1,000 - 40,000 FPS / 3-16 seconds of record time

Resolution

What is the level of detail required to capture the event?

Chronos range from 1280x1024 to 1920x1080HD max resolution.

Light Sensitivity

What is the lighting sensitivity/contrast required to capture the event?

Chronos range from ISO 320-16,000 depending upon model and sensor type (color or monochrome).

Subject Matter

What is the size and distance from the subject?

Chronos offers a selection of lenses from microscope to 12.5mm-75mm to capture events near or far.