Precision Redefined: Real-time DIC with Mercury RT and Chronos Cameras

Breaking New Ground with Mercury MS S.r.o. We’re thrilled to announce a new partnership between Kron Technologies…

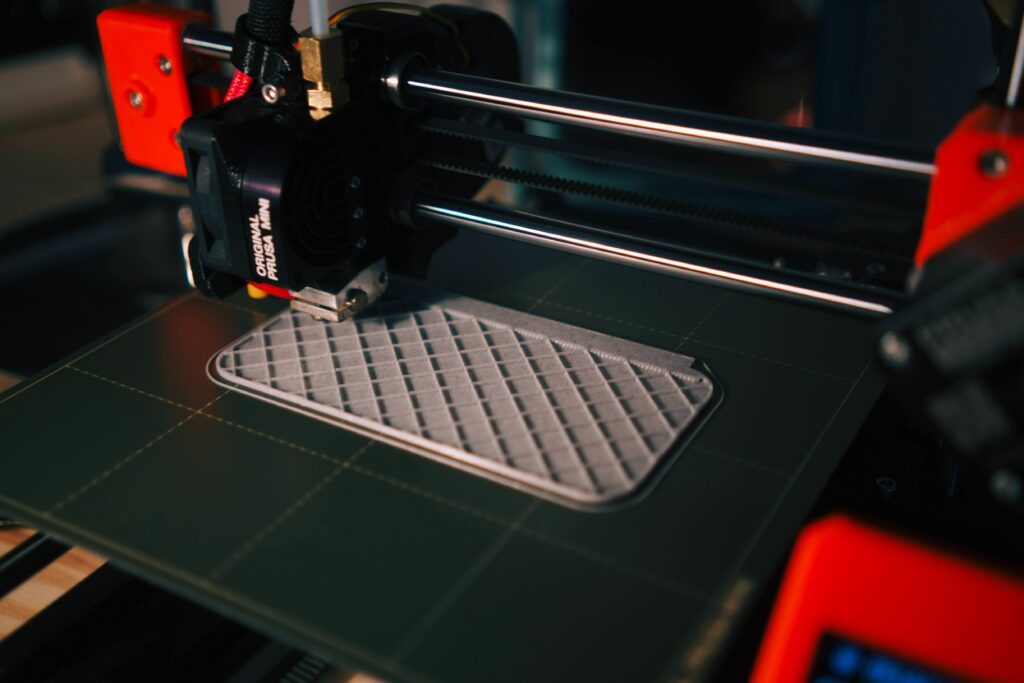

3D printing is rapidly transforming the way we prototype products, but it also comes with its fair share of challenges. From failed prints to inconsistent quality, achieving excellent results in 3D printing isn’t always easy. Fortunately, there’s an innovative solution that could revolutionize your 3D printing process: slow-motion analysis using a high speed camera. In this blog post, we’ll explore how using slow-motion analysis techniques using a high speed camera can help you identify and fix issues in your 3D printing process, leading to consistent and high-quality prints every time.

The three-dimensional printing process is a slow and often tedious one. But, with the right tools in place, it can be the key to improving your 3D printing processes.

First, let’s take a look at how the 3D printing process works. In general, there are three main steps to the process: modeling, slicing, and printing.

Modeling is the first step and involves creating a 3D model of the object you want to print. This can be done using CAD software or by scanning an existing object.

Slicing is the second step and involves breaking down the 3D model into thin layers that can be printed one at a time. This is usually done with special slicing software.

Printing is the third and final step. This is where the actual printing takes place, layer by layer, until the object is complete.

Photo by Gavin Allanwood on Unsplash

High speed camera slow-motion analysis is the key to perfecting your 3D printing process. By analyzing your print in slow motion via camera, you can identify any issues that may be causing problems with your print quality. This type of analysis can also help you to improve your print speed and accuracy. Additionally, slow-motion analysis can help you troubleshoot your 3D printer and make sure that it is functioning properly.

Another benefit of camera slow-motion analysis is that it can help you optimize your material usage. By analyzing your prints in slow motion, you can determine how much material is being used for each layer and make adjustments accordingly. This can help you save money on materials, as well as increase the efficiency of your 3D printing process overall.

Finally, slow-motion analysis with a high speed camera can also help you improve the safety of your 3D printing operation. By taking the time to analyze potential hazards in your print area, you can make changes to improve safety for both yourself and others working in the area.

Effects of High Thermal Gradients on 3D Printed Parts

As the world of Additive Manufacturing (AM) continues to evolve, so too do the challenges that end-users face. One such challenge is how to deal with high thermal gradients when printing 3D parts.

High thermal gradients can cause a number of problems for 3D printed parts, including warping, dimensional instability, and even mechanical damage. These effects can be disastrous for critical applications, and so it is important to understand how to mitigate them.

One way to combat the effects of high thermal gradients is by using slow-motion analysis. This technique allows users to see how their 3D printer is performing in real-time, and identify any potential issues before they become serious problems.

Slow-motion analysis with a Chronos camera can be used to optimize the printing process and ensure that parts are printed accurately and with minimal defects. This technique is particularly useful for those working with high thermal gradients, as it can help to prevent any damage or distortion that may occur.

In-Situ Sensing for Defect Detection

Utilizing a high speed camera for in-situ sensing is critical for detecting defects in 3D printing processes. By monitoring parameters such as temperature, humidity, and oxygen concentration in the build chamber, it is possible to identify potential issues that could lead to defects.

One of the benefits of in-situ sensing is that it can be used to detect defects early on in the process, before they become visible to the naked eye. This allows for corrective action to be taken before the defect becomes irreparable. Additionally, in-situ sensing can provide valuable data that can be used to optimize the 3D printing process overall.

There are a variety of different types of in-situ sensors available on the market today. Some of the most popular options include thermocouples, moisture sensors, and oxygen sensors. When choosing an in-situ sensor for your application, it is important to consider factors such as accuracy, precision, and sensitivity and how the camera will observe them.

Implementing Slow Motion Analysis in 3D Printing Processes

Utilizing a high-speed camera such as the Chronos 1.4 in additive manufacturing is easy. The high-resolution, high framerate, affordability, and ease-of-use make it a snap to implement in most 3d-printing setups.

Slow-motion analysis can be used to improve both the accuracy and repeatability of 3D printers. In terms of accuracy, engineers can use slow-motion analysis to observe how different materials deform under various printing conditions. This information can then be used to design better materials that are less likely to warp or deform during the printing process.

In terms of repeatability, engineers can use camera slow-motion analysis to identify areas where the print head may be skipping or not depositing material evenly. This information can then be used to make adjustments to the printer’s controls in order to improve print quality.

Benefits of Slow-Motion Analysis for Additive Manufacturing:

1. Increased accuracy: By being able to see the print head in action, manufacturers can make adjustments to improve accuracy and reduce waste.

2. Increased efficiency: Seeing and correcting problems in real-time can help speed up the production process and reduce downtime.

3. Improved quality: By catching and correcting errors early on, manufacturers can produce higher quality products that meet customer expectations.

Despite these advantages, there are some challenges that need to be considered when using slow-motion analysis for 3D printing. These include:

1. Cost: The equipment needed for slow-motion analysis can be expensive, which may limit its use to larger companies or those with deep pockets. However, the Chronos high-speed cameras series are the most affordable options in the marketplace and can potentially pay for themselves with improved printing efficiency.

2. Training: Operators need to be trained on how to use the equipment and interpret the data, which can take time and resources, though Chronos cameras are regarded as some of the easiest to use high-speed cameras in the industry.

3. Complexity: Some processes are too complex to be easily analyzed using this method, which can lead to false positives or incorrect results.

Conclusion

Slow-motion analysis with a high speed camera and 3D printing go hand in hand to ensure the best possible products for customers. By carefully analyzing each step of the process, you can identify potential problems and make adjustments before they become costly mistakes. As technology continues to evolve, slow motion analysis will remain a key part of perfecting 3D printing processes and helping businesses maximize their profits. With its ability to reveal the intricacies of any 3D printing job, there’s no doubt that it will continue to be an invaluable tool for years to come.

Stay up-to-date on the latest Chronos Camera tips, upgrades and news

Breaking New Ground with Mercury MS S.r.o. We’re thrilled to announce a new partnership between Kron Technologies…

Droplets deposited on a sufficiently hot surface experience an interesting phenomenon. They skid on a layer of…

Discover the power of Chronos high-speed cameras, designed to meet the demands of content creators and videographers.

Brief history of droplet impact The study of droplet impact can be traced back to the nineteenth…

In this article, we’d like to discuss another interesting topic: computational fluid dynamics, also referred to as...

Fluid mechanics describes the flow of fluid whether at rest or in motion1. The surface of the…